The TPW Automated Sample Preparation Workstation enhances laboratory productivity by minimizing resource allocation for repetitive tasks such as sample weighing, extraction, filtration, dilution, and transfer to analysis devices. This enables the re-purposing of lab staff to mission critical tasks such as data analysis, reporting, and notebook documentation. Automated procedures can also reduce solvent usage and hazardous waste generation while improving analyst safety by minimizing exposure to hazardous reagents and samples.

- Assay and content/blend uniformity for up to 100 samples

- 20 – 520 mL initial extraction volume

- Waters Empower™ Interface

- Powerful dEsign™ variables for streamlined DoE studies

- Video monitoring with VideoLink™

Highlights

Extraction

After weighing the sample, the TPW uses a high-shear homogenizer to provide a consistent wet grinding process to quickly extract samples. With this tool, the TPW can achieve efficient and reproducible extraction for even the most challenging dosage forms. Common sample types include traditional solid oral dosage forms including tamper-resistant products, osmotic pump, modified/extended and delayed release formulations. Cleaning between samples is easily programmed into the method to eliminate sample carry-over. The updated TPW is enhanced to reduce cycle times by adding efficiency to the clean-up and dilution processes.

Filtration and dilution

Consistent volumetric preparations are confirmed gravimetrically at every step throughout the process. The TPW uses a fluid metering pump to filter extracted samples as they are transferred from the extraction vessel to processing tubes. Post filtration, the system can perform up to 1:100,000 dilutions within a single method. For every sample, the system audit trail combined with the advanced error handling capabilities provides a detailed and comprehensive record of the entire preparation process.

Analysis and storage

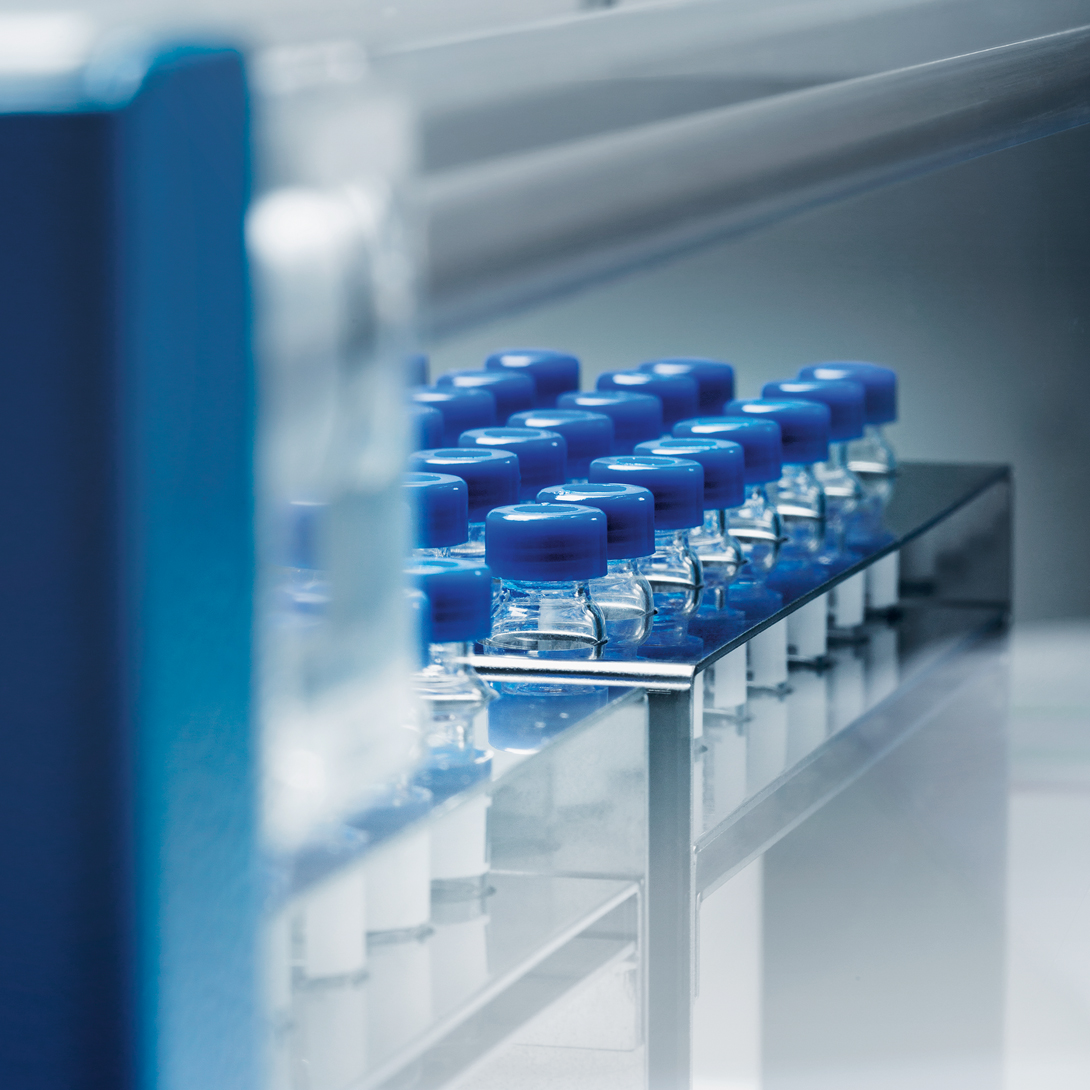

The built-in HPLC injector supports on-line analysis. Optionally, all pertinent sample information is transferred to Empower™ as the sample sequence is built by the interface as the TPW run list progresses. In addition to on-line HPLC analysis, samples can also be collected in sealed HPLC vials on the autosampler. Finally, the TPW has the capability to transfer samples to a UV spectrophotometer to act as an autosampler for on-line UV analysis.

Video monitoring

VideoLinkTM provides video recording of your sample extraction process when using the automated TPW workstation. One or two cameras can be set to trigger on specific events in the automated preparation process. Using this functionality, it is possible to easily associate a variety of key instrument activities that occur during an unattended run with a specific sample ID or preparation step.